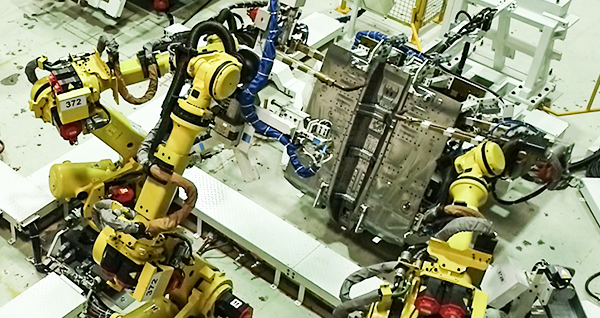

Faith Automation is a turnkey solution provider in the Body Welding Lines, both Robotic & Manual for Spot Welding as well as MIG Welding Applications. The organization offers enabling technical solutions and a robust turnkey project execution. We specialize in process planning and layout, including robot reach studies, simulation & offline programming, which play a crucial role in Robotic Spot Weld Lines.

Robotic Spot Welding Lines/Cells-BIW

MIG welding is one of Faith’s strong competencies, where robotic MIG welding solutions are offered, mainly for Chassis & Underbody safety assemblies like Chassis, Rear Axle – RTB, Sub Frames – FCM and Lower Cross Arm – LCA. The team of experts at Faith possess advanced skills in the robotic MIG welding lines. The team has many years of experience in executing MIG Welding Projects. As a result of this, the team can achieve best results with good penetration & minimum distortion. The robotics team at Faith have the experience of working with different combinations of robots and welding sources like Fanuc+ Lincoln, KUKA + Fronius, Panasonic etc.

Manual Spot Welding Lines – BIW

For low volume/low JPH (jobs-per-hour-rate) lines, Faith offers Manual Spot Welding Lines/Fixtures/Jigs. The design team takes utmost care of operator ergonomics (like loading height, reach, gun orientation and handling) as well as fatigue, while designing these manual welding fixtures/jigs. Manual Spot Welding Lines is for low volumes and the complete Bodyshop Solutions is provided.

Robotic MIG Welding Lines-Chassis

MIG welding is one of Faith’s strong competencies, where robotic MIG welding solutions are offered, mainly for Chassis & Underbody safety assemblies like Chassis, Rear Axle – RTB, Sub Frames – FCM and Lower Cross Arm – LCA. The team of experts at Faith possess advanced skills in the robotic MIG welding lines. The team has many years of experience in executing MIG Welding Projects. As a result of this, the team can achieve best results with good penetration & minimum distortion. The robotics team at Faith have the experience of working with different combinations of robots and welding sources like Fanuc+ Lincoln, KUKA + Fronius, Panasonic etc.

Roller Hemming – Closures

Faith has designed and installed lines/cells for Closures (Front Door LH/RH, Rear Door LH/RH, Hood, Tail Gate/Trunk Lid), starting with Inner Welding Cells, Outer Sealing Fixtures/Jigs, Pre-Hem/Pre-Marriage Fixtures/Jigs, Hemming (Roller Hemming and Press Hemming), after Hem Welding and Hinge Fitment. A highly experienced team at Faith supports customers by providing input on Hem Flange length and opening angle to get best hemming quality.