Faith Automation is involved in providing material handling for automatic transfering of the underbody and the main body from one station to the next. Material Handling are one of the most cost-effective equipments used to assemble parts with a unique design and long life cycle. They are also designed and installed to incorporate flexibility for future part changes as well. They also improve high-volume part production and help in re-tooling of the existing equipment for part changes. Faith has developed standards for the following:

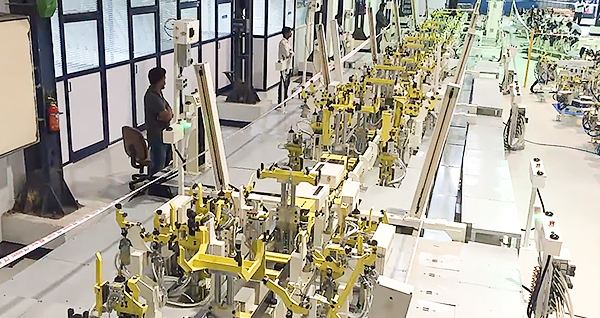

Shuttle Conveyors

Lift & Shift Transfers Line

Lift and Shift Shuttle Conveyors are a type of material handling equipments’. They are used to transfer a body from one station to the next. Following which, the empty shuttle returns back to the first station. In this system, there is no skid/pallet which is required to travel throughout the line. All transfers happen at the same time as the line is connected.

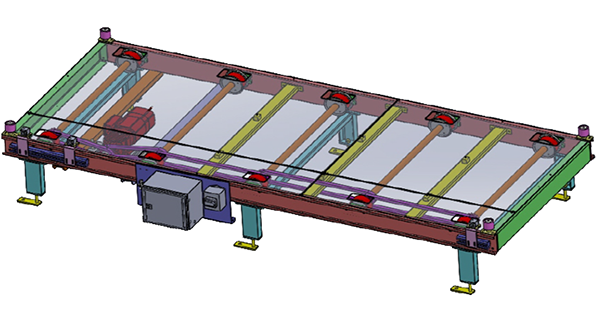

Skid/Pallet Transfer System

with Roller Bed

Skid/pallet through roller beds are widely used transfer systems in body shop. In this kind of material handling, the skid/pallet is first loaded onto the first station, post which the body is loaded onto it. The skid/pallet would ideally carry the body from the first station up until the last station, where the body would be unloaded and skid/ pallet would return to its start position.This is a flexible system where the in between station transfers can be managed independently.

Buffer Conveyors

Buffer Conveyors are important equipments in the body shop process. They are planned between two lines as contingency. In case of the first line breaking down, the production would not stop and will continue using the buffers. Belt type Buffer Conveyors operates using wide Belts & the Body/Sub Assembly is resting on the belt. The belt is driven with the help of a motor & gearbox. It is considered to be a low height equipment.

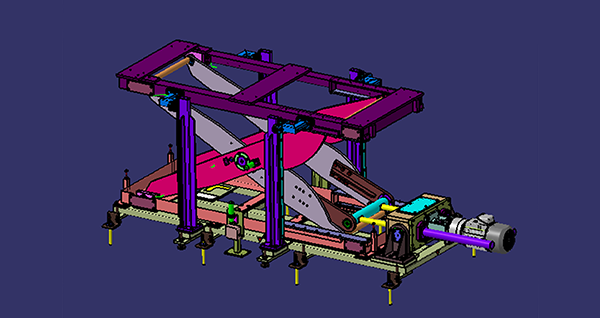

Scissor Lift

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.