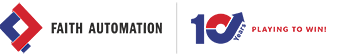

Faith Automation delivers complete solution for prototype bodies. Solutions ranging from designing and manufacturing of minimum welding fixtures to welding bodies/assemblies and supplying are delivered, as per the requirement of the customers. At Faith, confidentiality of a project/customer is of utmost importance, having multiple entry/exit for the shop floor. The organization strictly maintains the confidentiality of the Proto project.

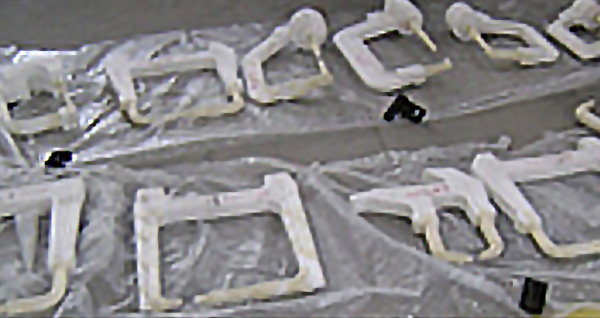

Simple Fixtures for

Proto Body Making

The design team at Faith has an experience of designing minimum welding fixtures. These welding fixtures are developed through multiple stages in the same fixture in order to build the proto body/assembly. The multiple stages are designed by using simple changeover or drop-out units, which makes it highly cost-effective.

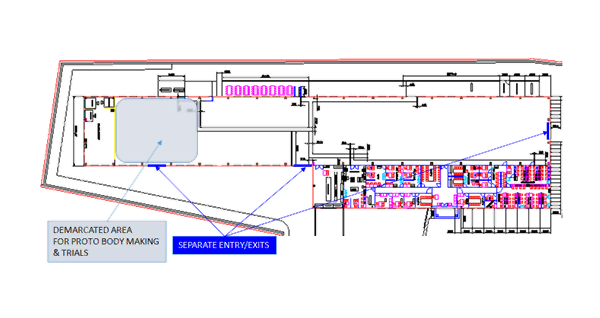

Weld Guns for

Proto Body Making

The team at Faith has an experience of building proto bodies/assemblies using minimum weld guns. The highly-skilled design team has the capability of selecting a combination of weld gun arms replaceable on couple of weld gun bodies. This leads to a major cost-saving on the project.

Proto Body

Assembly Making & Supply

Faith Automation houses an experienced team of professionals and a well-equipped facility to support the making of prototype bodies/assemblies. Having an in-house Inspection Facility, the organization delivers Proto Bodies/assemblies after conducting thorough quality checks.